The aims and purposes of lean production

-

Lean production is a management philosophy that aims to maximise value while minimising waste

-

It focuses on maximising efficiency, improving quality and reducing costs

-

Lean production is likely to lead to a competitive advantage

-

Lower unit costs are achieved due to minimal wastage so prices may be lower than those offered by competitors

-

Better quality of output is likely as a result of supplier reliability and carefully managed production processes

-

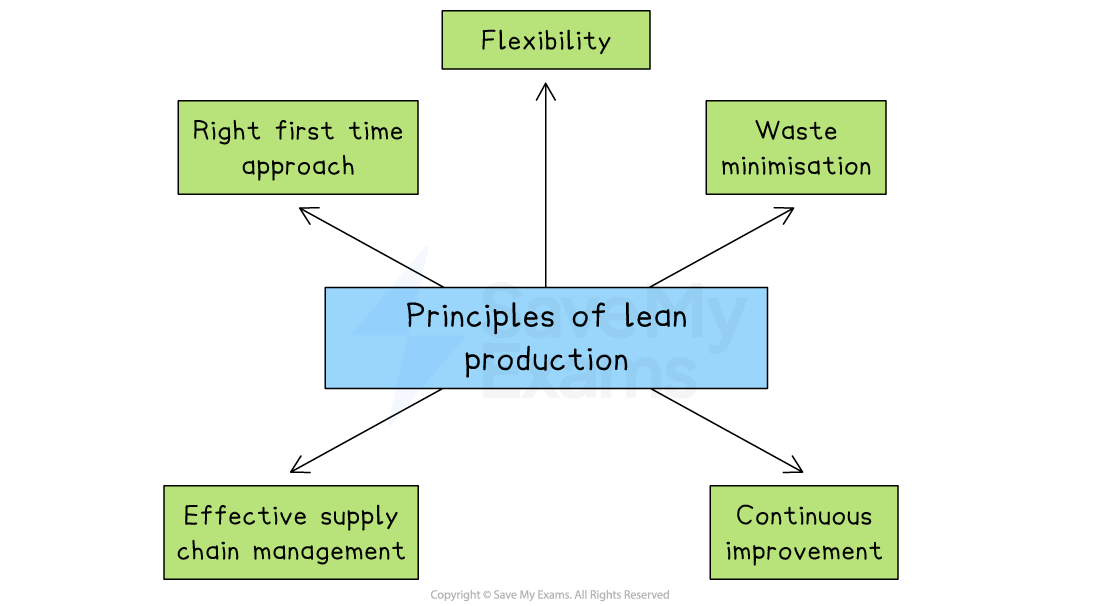

The main principles of lean production

-

Right first time approach

-

Aim for zero defects in output

-

Identify and solve problems as they arise

-

Prevent rather than correct errors

-

-

Flexibility

-

Adaptable capital equipment and physical resources

-

Multiskilled staff and team working

-

Flexible management styles

-

-

Waste minimisation

-

Remove processes that do not contribute to added value

-

Consume as little as is necessary

-

Rework rather than replace

-

-

Effective supply chain management

-

Develop excellent relationships with suppliers

-

Minimal number of suppliers

-

-

Continuous improvement

-

Ongoing, small steps

-

All staff involved in improvement

-

Lean production strategies

-

Businesses that pursue lean production can adopt a range of strategies

1. Kaizen

-

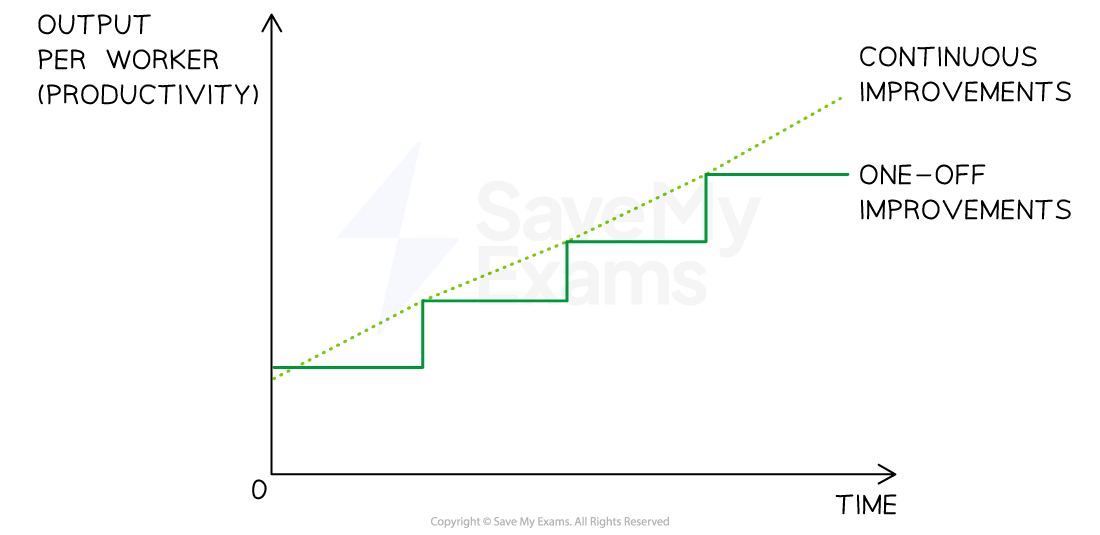

Kaizen means “continuous improvement” in Japanese

-

It involves small, regular changes made by employees at all levels

-

Workers are encouraged to suggest ways to improve efficiency, quality and processes

-

These ideas are implemented gradually over time

-

A comparison of Kaizen with one-off improvements

Evaluating the use of Kaizen

|

Advantages |

Disadvantages |

|---|---|

|

|

2. Quality circles

-

Small groups of employees who meet regularly to discuss work-related problems and suggest improvements

-

These groups usually focus on improving quality, safety or productivity and include workers from different levels of the business

Evaluating the use of quality circles

|

Advantages |

Disadvantages |

|---|---|

|

|

3. Simultaneous engineering

-

A production method where product development stages happen at the same time, rather than one after another

-

For example, design, engineering and marketing teams work together to reduce the time it takes to launch a new product

-

Evaluating the use of simultaneous engineering

|

Advantages |

Disadvantages |

|---|---|

|

|

4. Cell production

-

A method of organising production into small teams that complete a whole part of the product process

-

Instead of passing work along a production line, each cell is responsible for a complete unit of work, encouraging ownership and teamwork

Evaluating the use of cell production

|

Advantages |

Disadvantages |

|---|---|

|

|

5. Just-in-time manufacturing

-

Where products are made only when there is demand, and each stage of production begins only when needed by the next stage

-

This approach aims to match production with customer demand

-

This minimises waste, speeds up workflows, and reduces the need for warehousing

-

Evaluating the use of just-in-time manufacturing

|

Advantages |

Disadvantages |

|---|---|

|

|

6. Waste management

-

Waste can be anything that does not add value, such as overproduction, excess inventory, delays or defects

-

Lean waste management aims to simplify processes and reduce costs

Evaluating the use of waste management

|

Advantages |

Disadvantages |

|---|---|

|

|

The impact of lean production

-

Lean production affects not only how goods are made but also how people work, how quality is maintained and how inventoryis managed

Lean production impacts

|

Area of Impact |

Explanation |

|---|---|

|

Inventory Control |

|

|

Quality |

|

|

Employee roles |

|

|

Capacity management |

|

|

Efficiency |

|

Limitations of lean production strategies

-

Lean production can improve efficiency and reduce waste, but it also presents several challenges and limitations that businesses must carefully manage