Business_A-level_Aqa

-

1-1-the-nature-and-purpose-of-business3 主题

-

1-2-forms-of-business5 主题

-

1-3-the-external-environment5 主题

-

2-1-management-and-leadership3 主题

-

2-2-management-decision-making4 主题

-

2-3-the-role-and-importance-of-stakeholders3 主题

-

3-1-marketing-objectives1 主题

-

3-2-understanding-markets-and-customers5 主题

-

3-3-making-marketing-decisions2 主题

-

3-4-the-marketing-mix7 主题

-

4-1-operational-objectives2 主题

-

4-2-operational-performance1 主题

-

4-3-efficiency-and-productivity3 主题

-

4-4-quality1 主题

-

4-5-inventory-and-supply-chain-management3 主题

-

5-1-financial-objectives2 主题

-

5-2-financial-performance6 主题

-

5-3-sources-of-finance3 主题

-

5-4-cash-flow-and-profit1 主题

-

6-1-human-resource-objectives1 主题

-

6-2-human-resource-performance1 主题

-

6-3-organisational-design3 主题

-

6-4-human-resource-planning4 主题

-

6-5-motivation4 主题

-

6-6-improving-employer-employee-relations2 主题

-

7-1-mission-objectives-and-strategy4 主题

-

7-2-assessing-the-internal-position-of-a-business10 主题

-

7-3-changes-in-the-external-environment7 主题

-

7-4-the-competitive-environment1 主题

-

7-5-investment-appraisal2 主题

-

8-1-strategic-direction1 主题

-

8-2-strategic-positioning2 主题

-

9-1-changes-in-scale4 主题

-

9-2-innovation2 主题

-

9-3-globalisation-and-internationalisation4 主题

-

9-4-digital-technology1 主题

-

10-1-managing-change3 主题

-

10-2-organisational-culture2 主题

-

10-3-implementing-strategy2 主题

-

10-4-strategic-failure2 主题

inventory-control

The importance of effective inventory control

-

Inventory is everything a business owns today for the purpose of selling tomorrow

-

It is sometimes called stock, and the terms are used interchangeably

-

-

Businesses hold inventory for immediate use in production or to distribute without delay to customers

Types of inventory

|

Type |

Description |

Example |

|---|---|---|

|

Raw materials |

|

|

|

Components |

|

|

|

Work-in-progress |

|

|

|

Finished goods |

|

|

Influences on the level of inventory

-

Demand variability

-

The more sales fluctuate, the more buffer stock may be needed

-

-

Lead-time length and reliability

-

Long or unpredictable supplier lead times force firms to carry extra inventory

-

-

Product perishability

-

Goods that spoil quickly must be ordered in smaller batches

-

-

Storage capacity and cost

-

Limited warehouse space or high rent encourages lower inventory levels

-

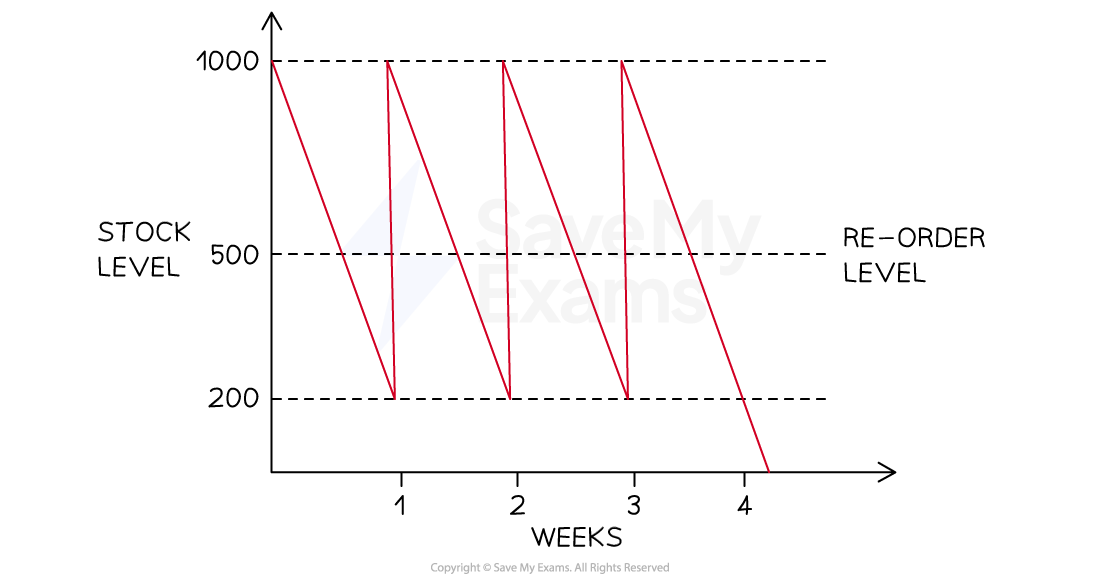

Inventory control charts

-

Inventory control involves carefully planning and controlling inventory flow to ensure that enough raw materials, work-in-progress and components are available to meet production demands

-

An inventory control diagram shows how inventory moves into and out of a business over time

An inventory control diagram

Diagram analysis

-

The maximum inventory level is the maximum amount of stock a business is able to hold in normal circumstances (1,600)

-

The reorder level is the level at which a business places a new order with its supplier (800)

-

The minimum stock level is also known as the buffer stock level and is the lowest level to which a business is willing to allow inventory levels to fall (400)

-

The lead time is the length of time from the point of inventory being ordered from the supplier to it being delivered (one week)

-

The stock level line shows how inventory levels change over the given time period

-

As inventory is used up, a downwards slope is plotted

-

When an order is delivered by a supplier, the stock level line shoots upwards

-

Examiner Tips and Tricks

For inventory control charts, show how reorder level, lead time and buffer stock work together — many students mix them up

Worked Example

The diagram below shows inventory movements of kitchen shelving units sold by TamFix Limited.

Identify the following points:

-

The minimum stock level

-

The reorder level

-

The reorder quantity

-

The lead time for kitchen shelving units

[4 marks]

Answer:

Step 1: Identify the minimum stock level

-

The minimum stock level is identified by the bottommost dotted line

-

In this case, it shows that the minimum stock level is 200 units (1)

Step 2: Identify the reorder level

-

The reorder level is clearly identified on the diagram

-

In this case, it shows that the reorder level is 500 units (1)

Step 3: Identify the reorder quantity

-

The reorder quantity is the difference between the maximum stock level (shown by the topmost dotted line) and the minimum stock level

-

The reorder quantity is, therefore, 800 units (1)

Step 4: Identify the lead time for kitchen shelving units

-

The lead time is the difference in time between the time an order is placed and the time the inventory is delivered

-

In this case, assuming a five-day working week, the lead time for shelving units is two days (1)

Examiner Tips and Tricks

Always clearly label your lead time, reorder level and buffer stock, and include units

Show your workings — examiners award method marks even if the final figure is off