Exam code:1BS0

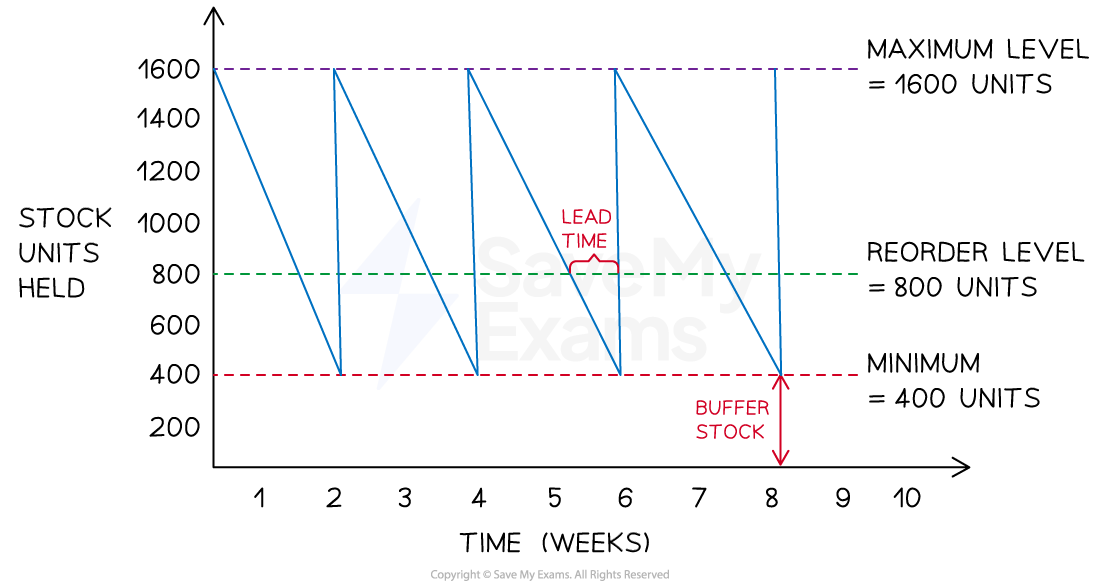

Interpretation of bar gate stock graphs

-

A Bar Gate Stock Control diagram illustrates the flow of stock (inventory) into and out of a business over time

Example Bar Gate Stock Graph

Diagram analysis

-

The maximum stock level is the maximum amount of stock a business is able to hold in normal circumstances (1600)

-

The reorder level is the level at which a business places a new order with its supplier (800)

-

The minimum stock level is also known as the buffer stock level and is the lowest level to which a business is willing to allow stock levels to fall (400)

-

The lead time is the length of time from the point of stock being ordered from the supplier to it being delivered (1 week)

-

The stock level line shows how stock levels change over the given time period

-

As stock is used up, a downwards slope is plotted

-

When an order is delivered by a supplier, the stock level line shoots upwards

-

Worked Example

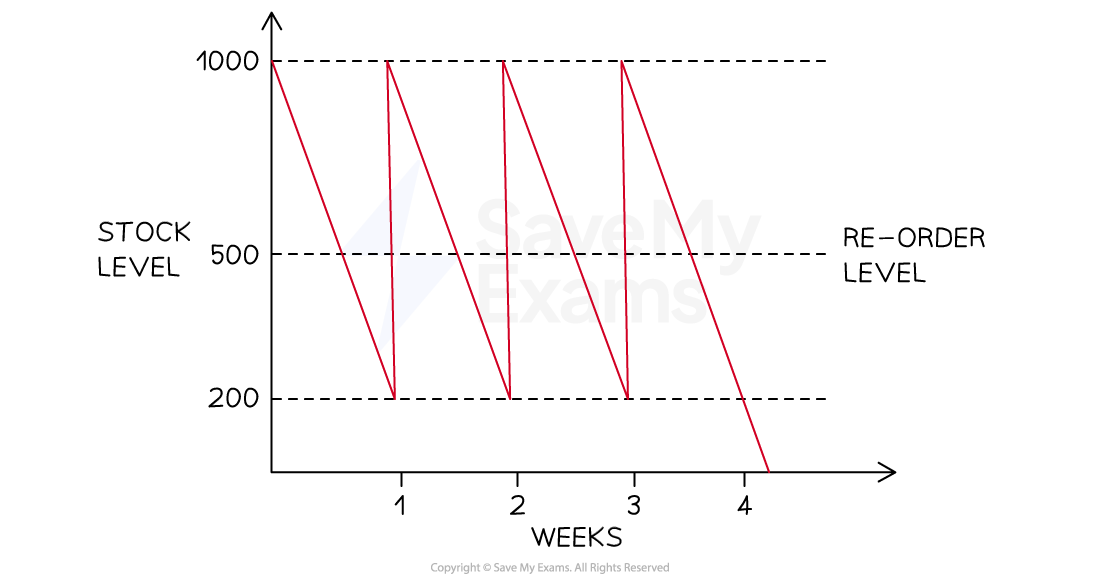

The diagram below shows stock movements of kitchen shelving units sold by TamFix Ltd.

Identify the following points:

-

the minimum stock level

-

the re-order level

-

the re-order quantity

-

the lead time for kitchen shelving units

(4)

Step 1: Identify the minimum stock level

-

The minimum stock level is identified by the bottom-most dotted line. In this case it shows that the minimum stock level is 200 units (1)

Step 2: Identify the reorder level

-

The reorder level is clearly identified on the diagram. In this case, it shows that the reorder level is 500 units (1)

Step 3: Identify the reorder quantity

-

The reorder quantity is the difference between the maximum stock level (shown by the topmost dotted line) and the minimum stock level

(1)

Step 4: Identify the lead time for kitchen shelving units

-

The lead time is the difference in time between an order for stock being placed and its delivery

-

In this case, assuming a five-day working week, the lead time for shelving units is two days (1)

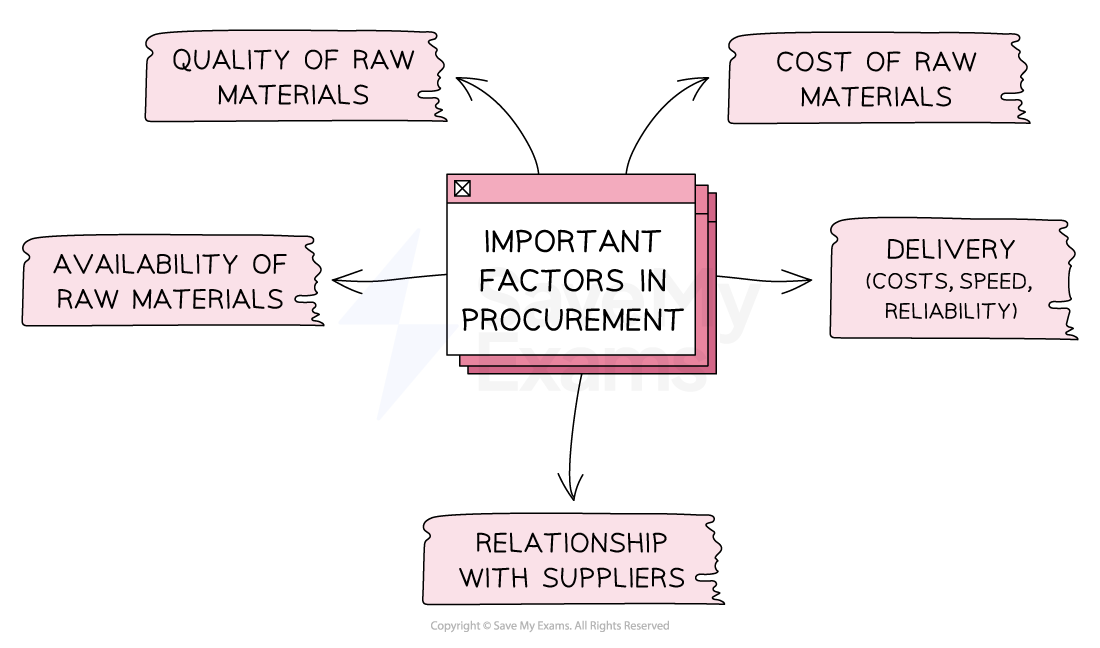

Efficient procurement of raw materials

-

Efficient procurement of raw materials is crucial for ensuring the success of any manufacturing process

-

There are several factors that can influence the efficiency of raw material procurement

Important factors in procurement

-

Businesses need to carefully consider these factors when sourcing raw materials to ensure that they can efficiently produce high-quality products at a reasonable cost

Factors that influence the sourcing of raw materials

|

Factor |

Explanation |

Example |

|---|---|---|

|

Quality |

|

|

|

Delivery |

|

|

|

Availability |

|

|

|

Costs |

|

|

|

Trust |

|

|

Just in time stock management

-

Just in Time (JIT) stock management is a process in which raw materials are not stored onsite but ordered as required and delivered by suppliers ‘just in time’ to be used

-

Careful coordination is required ensure that raw materials and components are delivered by suppliers at the moment that they are to be used

Responses