Exam code:9609

The purpose of inventory

-

Inventory is the goods and materials a business holds for the ultimate goal of resale or for use in production

Types of inventory

|

Raw materials |

Components |

|---|---|

|

|

|

Work-in-progress |

Finished goods |

|

|

Costs and benefits of holding inventory

-

The management of stock is an important consideration for businesses

-

Problems may arise from holding inventory

-

Storage costs (e.g. warehouse rental, security costs) will be higher than necessary

-

The risk of spoilage and stock shrinkage is increased, leading to increased costs

-

Money tied up in stock could be used elsewhere in the business

-

Time and resources are needed to monitor and track stock levels

-

-

However, if a business holds inventory, it means that

-

Products are available when needed, improving customer satisfaction

-

Buying quantities of inventory and storing it may reduce unit costs due to bulk buying discounts

-

Production isn’t held up by supply issues

-

Extra stock helps meet peaks in sales, such as during holiday periods

-

The importance of supply chain management

-

The supply chain is the network of organisations, people, activities and resources that move a product from its basic raw material right through to the final customer

-

It includes the following:

-

Stock control: planning, implementing and monitoring the movement of raw materials, components, work-in-progress and finished goods

-

Quality control: ensuring output meets standards so that the end product is safe and meets customer expectations

-

Transport networks: ensuring efficient deliveries of goods to customers, taking account of speed, reliability and costs

-

Supplier networks: developing strong relationships with suppliers willing to work collaboratively to improve quality

-

-

Global supply chains require these activities to be coordinated across international borders

-

Some stages can be completed at lower cost in certain countries

-

E.g. China has a reputation for producing high quality, low-cost electronics components

-

-

Labour-intensive processing, such as clothes manufacturing, is outsourced to countries with low labour costs, such as Vietnam

-

Scarce raw materials may only be available in certain countries/regions

-

Building an effective supply chain

|

Decision area |

What it involves |

|---|---|

|

Make or buy (produce in-house or outsource) |

|

|

Choosing suppliers |

|

|

Purchasing approach |

|

|

Information sharing and use of technology |

|

|

Logistics structure |

|

Why does an effective supply chain matter?

-

Faster delivery to customers

-

When every link is well-coordinated, products move quickly from factory to shelf, beating slower rivals

-

-

Lower operating costs

-

Just-in-time (JIT) deliveries and bulk purchasing agreements reduce storage, handling and material expenses

-

E.g. Aldi negotiates long-term contracts with a small group of trusted suppliers, helping it minimise warehouse inventory and keep prices low

-

-

Consistent quality

-

Close, long-term relationships with suppliers make it easier to enforce standards and fix problems early

-

-

Greater resilience to shocks

-

A well-planned supply chain includes backup suppliers and effective data sharing so the business can adapt when something goes wrong

-

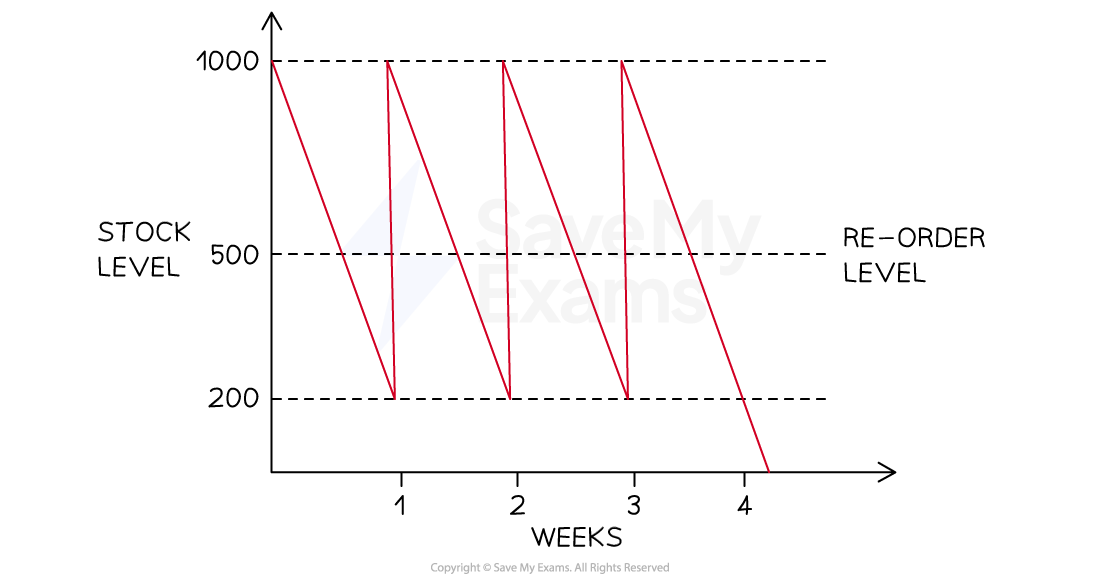

Inventory control charts

-

An inventory control diagram shows how inventory moves into and out of a business over time

An inventory control diagram

-

The maximum inventory level is the maximum amount of stock a business is able to hold in normal circumstances (1,600)

-

The reorder level is the level at which a business places a new order with its supplier (800)

-

The minimum stock level is also known as the buffer inventory level and is the lowest level to which a business is willing to allow inventory levels to fall (400)

-

Lead time is the length of time from the point of inventory being ordered from the supplier to it being delivered (one week)

-

The stock level line shows how inventory levels change over the given time period

-

As inventory is used up, a downwards slope is plotted

-

When an order is delivered by a supplier, the stock level line shoots upwards

-

Worked Example

The diagram below shows inventory movements of kitchen shelving units sold by TamFix Limited.

Identify the following points:

-

The minimum stock level

-

The reorder level

-

The reorder quantity

-

The lead time for kitchen shelving units

(4)

Answer:

Step 1: Identify the minimum stock level

-

The minimum stock level is identified by the bottommost dotted line

-

In this case, it shows that the minimum stock level is 200 units (1)

Step 2: Identify the reorder level

-

The reorder level is clearly identified on the diagram

-

In this case, it shows that the reorder level is 500 units (1)

Step 3: Identify the reorder quantity

-

The reorder quantity is the difference between the maximum stock level (shown by the topmost dotted line) and the minimum stock level

<img alt=”equals space 1000 space units space minus space 200 space units space equals space 800 space units” data-mathml=”<math ><semantics><mrow><mo>=</mo><mo> </mo><mn>1000</mn><mo> </mo><mi>units</mi><mo> </mo><mo>-</mo><mo> </mo><mn>200</mn><mo> </mo><mi>units</mi><mo> </mo><mspace linebreak=”newline”/><mspace linebreak=”newline”/><mo>=</mo><mo> </mo><mn>800</mn><mo> </mo><mi>units</mi></mrow><annotation encoding=”application/vnd.wiris.mtweb-params+json”>{“fontFamily”:”Times New Roman”,”fontSize”:”18″,”autoformat”:true,”toolbar”:”<toolbar ref=’general’><tab ref=’general’><removeItem ref=’setColor’/><removeItem ref=’bold’/><removeItem ref=’italic’/><removeItem ref=’autoItalic’/><removeItem ref=’setUnicode’/><removeItem ref=’mtext’ /><removeItem ref=’rtl’/><removeItem ref=’forceLigature’/><removeItem ref=’setFontFamily’ /><removeItem ref=’setFontSize’/></tab></toolbar>”}</annotation></semantics></math>” height=”69″ role=”math” src=”data:image/svg+xml;charset=utf8,%3Csvg%20xmlns%3D%22http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg%22%20xmlns%3Awrs%3D%22http%3A%2F%2Fwww.wiris.com%2Fxml%2Fmathml-extension%22%20height%3D%2269%22%20width%3D%22192%22%20wrs%3Abaseline%3D%2234%22%3E%3C!–MathML%3A%20%3Cmath%20xmlns%3D%22http%3A%2F%2Fwww.w3.org%2F1998%2FMath%2FMathML%22%3E%3Cmo%3E%3D%3C%2Fmo%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmn%3E1000%3C%2Fmn%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmi%3Eunits%3C%2Fmi%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmo%3E-%3C%2Fmo%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmn%3E200%3C%2Fmn%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmi%3Eunits%3C%2Fmi%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmspace%20linebreak%3D%22newline%22%2F%3E%3Cmspace%20linebreak%3D%22newline%22%2F%3E%3Cmo%3E%3D%3C%2Fmo%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmn%3E800%3C%2Fmn%3E%3Cmo%3E%26%23xA0%3B%3C%2Fmo%3E%3Cmi%3Eunits%3C%2Fmi%3E%3C%2Fmath%3E–%3E%3Cdefs%3E%3Cstyle%20type%3D%22text%2Fcss%22%3E%40font-face%7Bfont-family%3A’math143f4d31b04031e49f5eb18baba’%3Bsrc%3Aurl(data%3Afont%2Ftruetype%3Bcharset%3Dutf-8%3Bbase64%2CAAEAAAAMAIAAAwBAT1MvMi7iBBMAAADMAAAATmNtYXDEvmKUAAABHAAAADxjdnQgDVUNBwAAAVgAAAA6Z2x5ZoPi2VsAAAGUAAAA%2FGhlYWQQC2qxAAACkAAAADZoaGVhCGsXSAAAAsgAAAAkaG10eE2rRkcAAALsAAAADGxvY2EAHTwYAAAC%2BAAAABBtYXhwBT0FPgAAAwgAAAAgbmFtZaBxlY4AAAMoAAABn3Bvc3QB9wD6AAAEyAAAACBwcmVwa1uragAABOgAAAAUAAADSwGQAAUAAAQABAAAAAAABAAEAAAAAAAAAQEAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAACAgICAAAAAg1UADev96AAAD6ACWAAAAA

Responses