Exam code:7131

Managing the supply chain effectively

-

The supply chain is the network of organisations, people, activities and resources that move a product from its basic raw material right through to the final customer

-

It includes the following:

-

Stock control: planning, implementing and monitoring the movement of raw materials, components, work-in-progress and finished goods

-

Quality control: ensuring output meets standards so that the end product is safe and meets customer expectations

-

Transport networks: ensuring efficient deliveries of goods to customers, taking account of speed, reliability and costs

-

Supplier networks: developing strong relationships with suppliers willing to work collaboratively to improve quality

-

-

Global supply chains require these activities to be coordinated across international borders

-

Some stages can be completed at lower cost in certain countries

-

E.g. China has a reputation for producing high quality, low-cost electronics components

-

-

Labour-intensive processing, such as clothes manufacturing, is outsourced to countries with low labour costs, such as Vietnam

-

Scarce raw materials may only be available in certain countries/regions

-

Building an effective supply chain

|

Decision area |

What it involves |

|---|---|

|

Make or buy (produce in-house or outsource) |

|

|

Choosing suppliers |

|

|

Purchasing approach |

|

|

Information sharing and use of technology |

|

|

Logistics structure |

|

Why an effective supply chain matters

-

Faster delivery to customers

-

When every link is well-coordinated, products move quickly from factory to shelf, beating slower rivals

-

-

Lower operating costs

-

Just-in-time (JIT) deliveries and bulk purchasing agreements reduce storage, handling and material expenses

-

E.g. Aldi negotiates long-term contracts with a small group of trusted suppliers, helping it minimise warehouse inventory and keep prices low

-

-

Consistent quality

-

Close, long-term relationships with suppliers make it easier to enforce standards and fix problems early

-

-

Greater resilience to shocks

-

A well-planned supply chain includes backup suppliers and effective data sharing so the business can adapt when something goes wrong

-

Modern supply chains

-

Modern supply chains stretch across the world, rely on real-time data and face tough questions about ethics and sustainability

-

Businesses now use digital tools, closer partnerships and greener standards to keep those long chains working smoothly

Ways to manage more complex supply chains

|

Way |

Explanation |

Example |

|---|---|---|

|

Use live data to trace every item |

|

|

|

Predict problems with artificial intelligence (AI) |

|

|

|

Increase transparency for consumers and investors |

|

|

|

Share IT platforms and paperwork digitally |

|

|

|

Monitor operations with connected sensors |

|

|

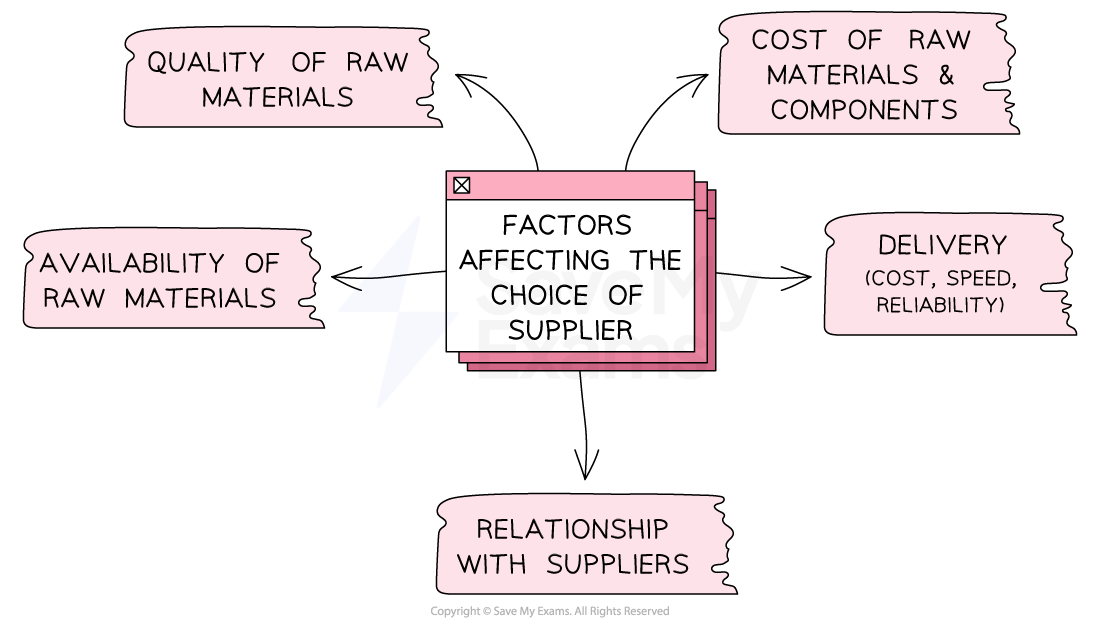

Influences on the choice of suppliers

-

Businesses often go to great lengths to find suitable suppliers of raw materials and components

-

Factors including the price, quality and reliability of supplies determine whether a business can efficiently produce high-quality products at a reasonable cost

-

-

There are several factors that can influence the supplier chosen by a business

Factors that guide the choice of supplier

|

Factor |

Why it matters |

|---|---|

|

Quality |

|

|

Delivery reliability |

|

|

Availability and supply security |

|

|

Price and payment terms |

|

|

Ethical and sustainability standards |

|

|

Relationship and trust |

|

|

Flexibility and responsiveness |

|

Examiner Tips and Tricks

Explain why reliability might outrank price for JIT firms, but price could still dominate for cost‑leaders

Weigh at least two factors before choosing a supplier to reach evaluation marks

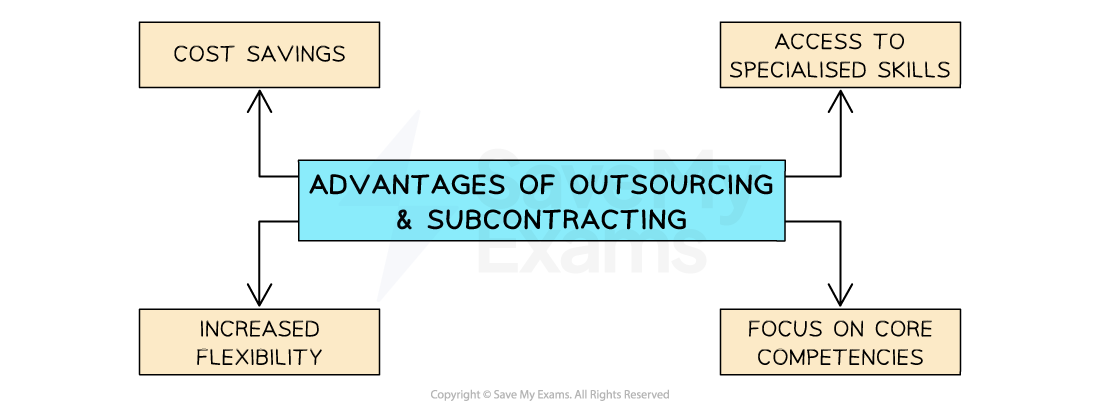

The value of outsourcing

-

Outsourcing is the process through which a business delegates specific business activities (IT, customer support, HR, etc.) to external service providers

-

Businesses choose to outsource these functions to reduce costs, access specialised expertise or focus on core competencies

-

Advantages of outsourcing

-

Cost savings

-

Businesses can often reduce expenses associated with operations such as hiring and training employees, maintaining infrastructure and managing IT systems

-

-

Access to specialised skills

-

External specialists have resources that the business lacks internally, whic

-

Responses