Business_A-level_Edexcel

-

1-marketing-and-people

1-1-meeting-customer-needs3 主题 -

1-2-market5 主题

-

1-3-marketing-mix-and-strategy5 主题

-

1-4-managing-people5 主题

-

1-5-entrepreneurs-and-leaders6 主题

-

2-managing-business-activities2-1-raising-finance4 主题

-

2-2-financial-planning4 主题

-

2-3-managing-finance3 主题

-

2-4-resource-management4 主题

-

2-5-external-influences3 主题

-

3-business-decisions-and-strategy3-1-business-objectives-and-strategy4 主题

-

3-2-business-growth4 主题

-

3-3-decision-making-techniques4 主题

-

3-4-influences-on-business-decisions4 主题

-

3-5-assessing-competitiveness3 主题

-

3-6-managing-change3 主题

-

4-global-business4-1-globalisation5 主题

-

4-2-global-markets-and-business-expansion5 主题

-

4-3-global-marketing3 主题

-

4-4-global-industries-and-multinational-corporations3 主题

-

5-exam-technique5-1-the-exam-papers4 主题

-

5-2-business-studies-skills1 主题

-

5-3-structuring-your-responses5 主题

-

6-pre-release-preparation2025-pre-release-music-industry9 主题

2-4-4-quality-management

Quality management methods

-

Quality considers the characteristics and features of a product that satisfy the needs of customers

-

Businesses need to maintain a level of quality that continues to attract and retain customers

-

There are several approaches to managing quality in the production process

Methods of quality management

|

Method |

Explanation |

|---|---|

|

Quality control |

|

|

Quality assurance |

|

|

Quality circles |

|

|

Total quality management |

|

Continuous improvement (kaizen)

-

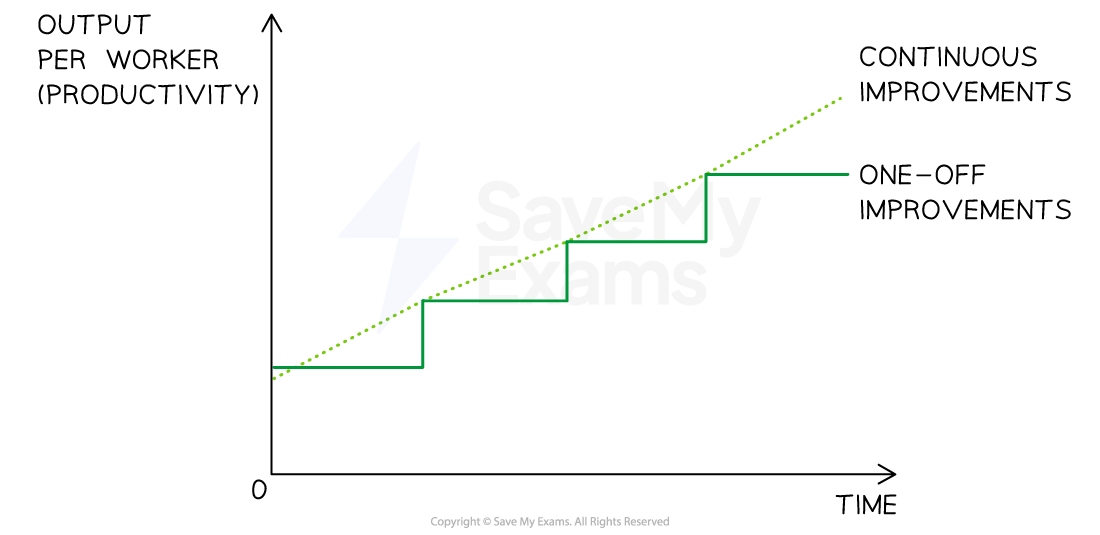

Kaizen involves a business taking continuous steps to improve productivity through the elimination of all types of waste in the production process

-

Changes are small and ongoing rather than significant one-offs, and they are constantly reviewed to ensure that the desired positive impact on productivity is achieved

-

Comparison of kaizen and one-off improvements

-

Elements of kaizen commonly include:

-

Total quality management

-

Just-in-time stock management

-

Teamwork and quality circles

-

Zero defects in manufacturing

-

High levels of automation

-

High levels of cooperation between workers and management

-

-

Kaizen requires a long-term management commitment to change

Competitive advantage from quality management

-

The quality of a business’s products can provide a competitive advantage

-

Unit costs are likely to be low if a business takes a preventative approach through the use of quality assurance or total quality management

-

Low costs may allow a business to reduce its selling price to better compete with or undercut its rivals

-

-

Increased finance may be available to fund marketing activity to improve brand recognition and attract new customers

-

High levels of quality can be used in promotional activity and provide a unique selling point for businesses in competitive markets

-

Successfully developing a unique selling point for quality can ease expansion into new markets as a result of the positive reputation it creates

-

Responses